Secondary processes may be required depending on part requirements. Through feed centerless grinding and centerless superfinishing are two very high speed / low-cost processes we offer to meet tight tolerance and surface finish requirements. We offer automated high speed and manual vision inspection methods to 100% for dimensional or cosmetic requirements. Outsourced operations include plating, heat treat, thermal deburring, and cold forming of part blanks when required.

The Importance of Secondary Processes in Precision Machining

Precision machining is not just a mechanical process but a work of art that requires meticulous attention to detail. At Griner Engineering, we understand that the quality of our precision-machined parts is a reflection of our expertise and dedication to our craft. That's why we go above and beyond to ensure that every part that leaves our facility is of the highest quality.

Secondary processes are an integral part of precision machining, as they are necessary to achieve specific part requirements. Without these processes, even the most precise machining may fall short of the required surface finishes or tolerances. Therefore, it is crucial to understand the importance of secondary manufacturing processes and the different methods used to achieve them.

By understanding the importance of secondary processes, we can appreciate the level of detail and expertise required to produce high-quality precision machined parts. So join us on this journey and discover the world of secondary processes and their critical role in precision machining.

What are Secondary Processes?

Have you ever wondered how precision machined parts achieve the flawless surface finishes and tight tolerances required for various industries, such as aerospace and medical? The answer lies in secondary processes, which are the additional steps required beyond the initial machining process.

Secondary processes are essential to achieving the specific surface finishes, tolerances, and cosmetic requirements that cannot be attained through machining alone. These processes include specialized techniques such as through-feed centerless grinding and centerless superfinishing, which are designed to remove material and polish surfaces to perfection.

The Role of Secondary Processes in Precision Machining

Precision machining is a highly intricate process that demands the highest quality standards. It is not enough to simply achieve the necessary tolerances and dimensions—the final product must also have a polished finish and an impeccable cosmetic appearance. That's where secondary processes come in.

Secondary processes are not just about achieving an aesthetically pleasing appearance but also about ensuring the end user's safety. Burrs, sharp edges, and other imperfections can pose safety hazards, especially in industries such as aerospace and medical. Secondary processes help remove these hazards, ensuring the safety and reliability of the final product.

At Griner Engineering, we understand the critical role that secondary manufacturing processes play in precision machining. That's why we invest in the latest technology and the most skilled technicians to provide a wide range of secondary processes, including through-feed centerless grinding and superfinishing. With our commitment to quality and precision, you can trust that every part we produce will meet or exceed the requirements for its intended use.

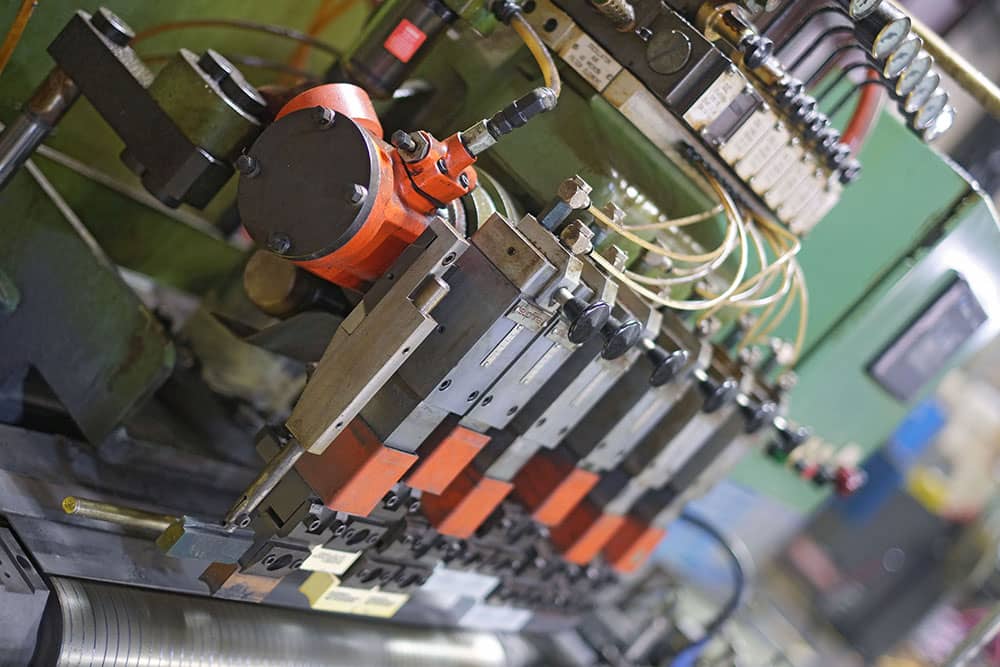

Through-Feed Centerless Grinding

If you are looking for a way to achieve precise, consistent results in high-volume production, through-feed centerless grinding may be just what you need. This specialized secondary process utilizes a grinding wheel to remove material from cylindrical parts, resulting in tight tolerances and a smooth surface finish.

What makes through-feed centerless grinding so effective is its high-speed, low-cost nature. It can quickly and efficiently remove material from parts, making it an ideal choice for high-volume production runs. And because the process is so consistent, you can expect uniform results from one part to the next.

At Griner Engineering, we are experts in through-feed centerless grinding, using the latest technology and equipment to deliver the precise results our clients demand. Whether you need a few parts or a few thousand, we have the capability to produce them with the tight tolerances and smooth surface finishes required for critical applications.

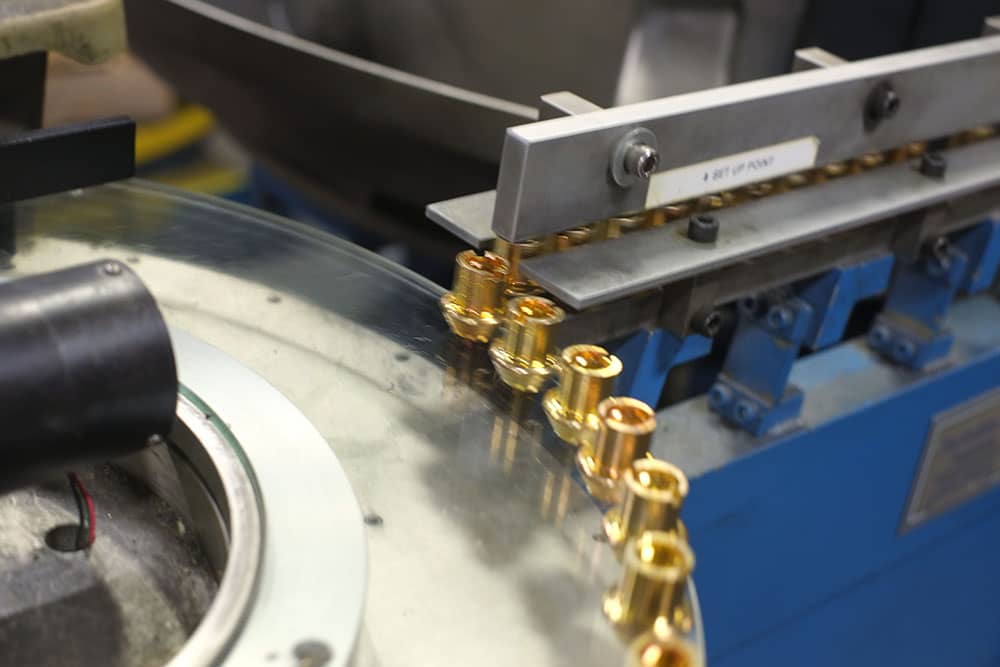

Centerless Superfinishing

If you are in the market for parts requiring a mirror-like surface finish, you must know about centerless superfinishing. This specialized secondary process utilizes a unique tool to achieve an ultra-smooth finish ideal for medical and aerospace applications.

Unlike other finishing processes, centerless superfinishing can achieve a surface finish of less than one microinch, ensuring that your parts meet even the strictest of specifications. And because it removes any remaining burrs or sharp edges, you can be confident that your parts will be safe and reliable.

At Griner Engineering, we are experts in centerless superfinishing, and we have helped countless clients achieve the high-quality surface finishes they need. Whether you are producing parts for the medical or aerospace industries, or any other application that demands precision and excellence, we can help you achieve the desired results.

Inspection Methods for Dimensional and Cosmetic Requirements

At Griner Engineering, we are committed to delivering high-quality parts that meet or exceed our customers' expectations. That's why we offer both automated high-speed and manual vision inspection methods to ensure that every part we produce meets the necessary dimensional and cosmetic requirements.

Our state-of-the-art inspection methods allow us to catch any defects or inconsistencies before they leave our facility, ensuring that every part you receive is of the highest quality. And because we know that every customer's needs are different, we offer both automated and manual inspection options to best suit your specific requirements.

With our advanced inspection methods, you can be confident that every part you receive will meet the necessary dimensional and cosmetic requirements, ensuring your complete satisfaction.

Outsourced Operations — Plating, Heat Treat, Thermal Deburring, and Cold Forming

Precision machining is just one part of the equation when it comes to producing high-quality parts. That's why we offer a range of outsourced operations, including plating, heat treating, thermal deburring, and cold forming, to help our clients achieve the specific material properties or surface finishes they need.

Whether you are looking to improve corrosion resistance, increase surface hardness, or remove burrs and sharp edges, we have the expertise and resources to get the job done. Our trusted network of partners ensures that every outsourced operation meets our strict quality standards, so you can be confident that the final product will meet or exceed your expectations.

So if you are looking for a partner that can provide end-to-end solutions for your precision machining needs, look no further than Griner Engineering. From initial machining to secondary manufacturing processes and outsourced operations, we have the experience and expertise to deliver the quality and precision you need to succeed.

Final Thoughts

At Griner Engineering, we understand that precision machining is a complex process that requires a keen eye for detail and a deep understanding of the materials and tools involved. That's why we go above and beyond to ensure that every part we produce meets our customers' exacting standards.

So whether you need a single precision machined part or a high-volume production run, you can count on Griner Engineering to deliver the quality and precision you need to succeed. Contact us today to learn more about our services and how we can help you achieve your production goals.